- होम पेज

- कंपनी प्रोफाइल

-

हमारे उत्पाद

- Frp pultruded उत्पाद

- FRP / GRP ढाला झंझरी

- FRP / GRP सजावटी प्रकाश पोल

- Frp pultrusion प्रोफ़ाइल

- FRP / GRP कैनोपीज़

- एफआरपी / जीआरपी केबल ट्रे

- फाइबर ग्लास उत्पाद

- सीढ़ी

- FRP कस्टम लैडर और संरचना

- जीआरपी लैडर्स

- फाइबरग्लास सीढ़ी

- एफआरपी सीढ़ी

- फाइबरग्लास सेल्फ सपोर्टेड लैडर

- फाइबरग्लास सेल्फ सपोर्टेड टू वे लैडर

- फाइबरग्लास वॉल सपोर्टेड लैडर

- फाइबरग्लास सेल्फ सपोर्टेड प्लेटफॉर्म लैडर

- फाइबरग्लास स्टेप स्टैंड लैडर

- फाइबरग्लास एक्सटेंशन टेलिस्कोपिक लैडर

- फाइबरग्लास मोबाइल प्लेटफ़ॉर्म सीढ़ी

- फाइबरग्लास मेंटेनेंस प्लेटफॉर्म लैडर

- फाइबरग्लास मैनहोल सीढ़ी

- फाइबरग्लास मोबाइल टेलीस्कोपिक प्लेटफार्म सीढ़ी

- फाइबरग्लास मोबाइल टेलीस्कोपिक टिल्टिंग लैडर

- फाइबरग्लास सेफ्टी केज्ड लैडर

- फाइबरग्लास सेल्फ सपोर्टेड लैडर्स

- टू साइड मैकेनिकल स्टेप लैडर

- फाइबरग्लास प्लेटफार्म सीढ़ी

- फाइबरग्लास मोबाइल प्लेटफ़ॉर्म लैडर्स

- सुरक्षा पिंजरे की सीढ़ी

- एफआरपी लैडर्स

- एफआरपी वॉल सपोर्ट एक्सटेंशन लैडर

- फाइबरग्लास सुरक्षा सीढ़ी

- स्टेप फोल्डिंग लैडर

- एफआरपी एक्सेस लैडर

- एफआरपी बहुउद्देशीय सीढ़ी

- फाइबर प्रबलित पॉलिमर सीढ़ी

- एफआरपी सुरक्षा सीढ़ी

- वेयरहाउस मोबाइल प्लेटफ़ॉर्म लैडर्स

- बाड़ लगाना

- केबल क्लैट

- सामग्री धारण करना

- FRP प्रोफाइल

- एफआरपी स्क्वायर पल्ट्रूडेड प्रोफाइल

- Aeron FRP प्रोफ़ाइल

- फाइबरग्लास पल्ट्रूडेड स्टैंडर्ड प्रोफाइल

- फाइबर प्रबलित प्लास्टिक प्रोफाइल

- FRP संरचनात्मक आकृतियाँ

- फाइबरग्लास स्ट्रक्चरल बीम्स

- एरोन ग्लास फाइबर प्रोफाइल

- FRP कूलिंग टॉवर प्रोफाइल

- FRP प्रोफ़ाइल

- एफआरपी एंगल प्रोफाइल

- फाइबरग्लास प्रोफाइल

- एफआरपी ट्यूब प्रोफाइल

- FRP स्ट्रक्चरल प्रोफाइल

- एफआरपी पल्ट्रूडेड प्रोफाइल

- FRP Box प्रोफ़ाइल

- FRP खोखला अनुभाग

- FRP चैनल

- FRP C चैनल प्रोफ़ाइल

- एफआरपी एपॉक्सी पल्ट्रूडेड प्रोफाइल

- फाइबर प्रबलित प्रोफ़ाइल

- जीआरपी प्रोफाइल

- कूलिंग टावर्स सॉल्यूशंस

- कार्बन फाइबर रॉड

- सौर -बढ़ती संरचना

- केबल ट्रे

- इलेक्ट्रिकल केबल ट्रे

- एफआरपी लैडर केबल ट्रे

- एफआरपी फ्लेक्सिबल केबल ट्रे

- एफआरपी लैडर केबल ट्रे

- फाइबर प्रबलित सीढ़ी केबल ट्रे

- एफआरपी एडजस्टेबल स्प्लिस प्लेट्स

- एफआरपी कपलर स्प्लिस प्लेट

- कवर के साथ केबल ट्रे

- ग्लास फाइबर केबल ट्रे

- एफआरपी केबल ट्रे

- केबल ट्रे कवर

- एफआरपी लैडर टाइप केबल ट्रे

- कवर के साथ FRP केबल ट्रे

- फाइबर प्रबलित प्लास्टिक केबल ट्रे

- लैडर केबल ट्रे

- फाइबरग्लास केबल ट्रे

- FRP gratings

- वॉकवे एफआरपी ग्रेटिंग

- एफआरपी मोल्डेड ग्रेटिंग

- आयताकार एफआरपी झंझरी

- एफआरपी पल्ट्रूडेड ग्रेटिंग

- एफआरपी कवर टॉप ग्रेटिंग

- FRP प्लेटफ़ॉर्म ग्रेटिंग

- कम्पोजिट ग्रेटिंग

- एफआरपी इनबिल्ट ग्रिट टॉप ग्रेटिंग

- एफआरपी कॉन्केव टॉप ग्रेटिंग

- एफआरपी ग्रेटिंग

- फाइबर प्रबलित झंझरी

- मोल्ड फाइबरग्लास ग्रेटिंग

- एफआरपी पल्ट्रूडेड फाइबरग्लास ग्रेटिंग

- अवतल सतह एफआरपी झंझरी

- एफआरपी वॉकवे

- रूफटॉप के लिए एफआरपी वॉकवे

- ग्लास फाइबर ग्रेटिंग

- वाणिज्यिक एफआरपी ग्रेटिंग्स

- एफआरपी फ्लोर ग्रेटिंग

- फाइबरग्लास फ्लोर प्लेट

- फाइबरग्लास ग्रेटिंग सिस्टम

- फुंसी हैंड्रिल

- FRP मॉड्यूल सौर पैनल बढ़ते संरचना

- जीआरपी क्लैंप

- बिजली के खंभे

- FRP रॉड शक्ति सदस्य

- फुफ्फुसीय चादर

- FRP उत्पाद

- Frp canopies

- जीआरपी ग्रैटिंग

- जीआरपी एप्लाइड ग्रिट टॉप ग्रेटिंग

- GRP ग्रेटिंग सिस्टम

- जीआरपी इनबिल्ट ग्रिट ग्रेटिंग

- जीआरपी वॉकवे ग्रेटिंग

- औद्योगिक जीआरपी ग्रेटिंग

- स्क्वायर जीआरपी ग्रेटिंग

- जीआरपी पल्ट्रूडेड ग्रेटिंग

- जीआरपी फ्लोर ग्रेटिंग

- जीआरपी ग्रेटिंग

- फाइबरग्लास मोल्डेड जीआरपी ग्रेटिंग

- जीआरपी मेश ग्रेटिंग्स

- जीआरपी फाइबरग्लास ऑयल प्लेटफॉर्म ग्रेटिंग

- पल्ट्रूडेड फाइबरग्लास ग्रेटिंग

- जीआरपी ऑयल प्लेटफॉर्म ग्रेटिंग

- जीआरपी कवर टॉप ग्रेटिंग

- जीआरपी मोल्डेड ग्रेटिंग

- जीआरपी केबल ट्रे

- ग्लास फाइबर प्रबलित केबल ट्रे

- GRP केबल ट्रे

- इलेक्ट्रिकल जीआरपी केबल ट्रे

- जीआरपी कवर छिद्रित केबल ट्रे

- कवर के साथ GRP केबल ट्रे

- जीआरपी लैडर टाइप केबल ट्रे

- स्ट्रेट फ्लेंज जीआरपी केबल ट्रे

- GRP वॉटरप्रूफ केबल ट्रे

- जीआरपी पल्ट्रूडेड केबल ट्रे

- GRP केबल ट्रे

- कवर के साथ GRP केबल ट्रे

- पल्ट्रूडेड इलेक्ट्रिकल जीआरपी केबल ट्रे

- जीआरपी सीढ़ी

- जीआरपी वॉल सपोर्टेड लैडर्स

- जीआरपी प्लेटफार्म लैडर्स

- GRP मोबाइल टेलीस्कोपिक प्लेटफ़ॉर्म लैडर्स

- जीआरपी स्ट्रक्चर लैडर्स

- जीआरपी सेल्फ सपोर्टेड लैडर्स

- जीआरपी मेंटेनेंस लैडर्स

- फाइबरग्लास स्टेप स्टैंड लैडर्स

- जीआरपी सेफ्टी केज्ड लैडर्स

- जीआरपी स्टेप लैडर

- जीआरपी एक्सेस लैडर

- हैवी ड्यूटी जीआरपी लैडर्स

- जीआरपी टू वे लैडर्स

- एफआरपी सुरक्षा मार्कर

- कार्बन फाइबर उत्पाद

- फ्रॉप क्रॉस आर्म

- जीआरपी उत्पाद

- Frp सीढ़ी ट्रेड

- Frp i बीम

- अतिरिक्त लिंक

- संपर्क करें

एफआरपी पल्ट्रूडेड ग्रेटिंग्स

2000 आईएनआर/Meter

उत्पाद विवरण:

- उपयोग औद्योगिक उपयोग के लिए

- शेप रेक्टेंगल

- प्रॉडक्ट टाइप कर्कश

- मटेरियल एफ आर पी

- अधिक देखने के लिए क्लिक करें

X

एफआरपी पल्ट्रूडेड ग्रेटिंग्स मूल्य और मात्रा

- मीटर/मीटर

- मीटर/मीटर

- 50

एफआरपी पल्ट्रूडेड ग्रेटिंग्स उत्पाद की विशेषताएं

- एफ आर पी

- रेक्टेंगल

- कर्कश

- औद्योगिक उपयोग के लिए

एफआरपी पल्ट्रूडेड ग्रेटिंग्स व्यापार सूचना

- कैश इन एडवांस (CID) कैश एडवांस (CA)

- 500 प्रति दिन

- 1 हफ़्ता

- ऑल इंडिया

उत्पाद वर्णन

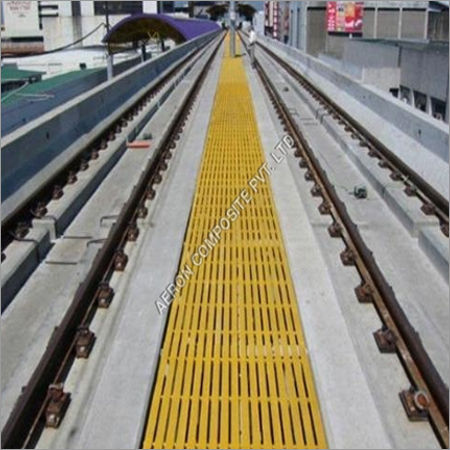

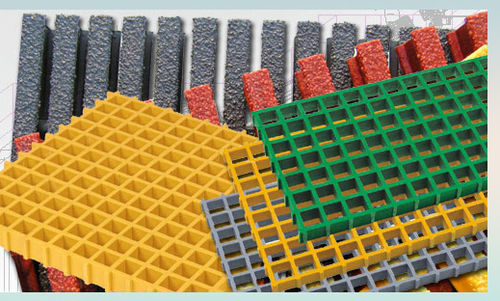

FRP Pultruded Gratings

With the support of our talented team of engineers and researchers, we are engaged in manufacturing, supplying and exporting FRP Pultruded Gratings. Under the strict guidance of our skilled manpower, these pultruded gratings are manufactured using supreme quality of FRP materials. Well known among our clients for their robust construction, high strength and corrosion resistance nature, these gratings are ideal for pedestrian walkways, platform, elevated car parking and step treads. Furthermore, clients can get FRP Pultruded Gratings from us at market leading prices.

Integrating durability, corrosion resistance, and a low-maintenance construction, Aeron pultruded grating systems are superior in comparison to conventional metallic gratings. This confirms that FRP pultruded gratings are manufactured with a lower level tie bar design and easier to fabricate and is light weight. Savings on equipment and workforce often make the combined introduced cost of Aeron FRP pultruded gratings almost similar to that of the steel. Our innovative pultruded gratings are fabricated and are intended for application in a broad variety of latest uses which necessitate corrosion resistance and quality.

Fixing Sets

Stainless steel fixing sets are taken into use for all the high quality FRP gratings and maintain constructions. To protect FRP gratings flawlessly against sliding and lifting away every panel should be fixed on minimum four points.

M CLIPS

Saddle clips or M Clips hold tightly 2 fibre glass grating load bars to maintain. This offers unmatched holding capability and due to this, these are suggested for stair treads and pultruded and molded fiber glass gratings.

Applications:

Trench covers | Staircase | Floorings | Foot Bridges | Swimming pool overflow | Fencing | | Earth pit covers

Industry:

Chemical | Food & Beverage | Marine | Oil & Gas | Power | Industry | Buildings | Constructions | Pharmaceuticals | Pulp & Paper | Recreation | Water & Waste Treatment | Shipping | Transportation |

Aeron offer Pultruded Grating, which is stronger than Moulded Gratings in longitudinal directions. It is fabricated from grove bar assemblies, bearing bars and interlocking rods. The bearing bars are pultruded I bars and T sections and available in 25mm (1 inch) and 38mm (1.5 inch) deep.

Size:

|

|

H- Height |

W- Top Width |

C- Spacing |

Open Area |

|

I-1040 |

25 |

15 |

25 |

40% |

|

I-1050 |

25 |

15 |

30 |

50% |

|

I-1060 |

25 |

15 |

38 |

60% |

|

I-1540 |

38 |

15 |

25 |

40% |

|

I-1550 |

38 |

15 |

30 |

50% |

|

I-1560 |

38 |

15 |

38 |

60% |

|

T-1033 |

25 |

25 |

38 |

33% |

|

T-1050 |

25 |

25 |

50.8 |

50% |

|

T-1517 |

38 |

25 |

30.5 |

17% |

|

T-1533 |

38 |

25 |

38 |

33% |

|

T-1550 |

38 |

25 |

50.8 |

50% |

All dimension in mm For Customised Size and Loading Chart please contact us

Resin Selection:

For maintenance free flooring solutions, Aeron FRP Grating is the perfect choice. It is made with an appropriate resin that makes the product high performing in the most demanding situations. Our grating is available in four standard resin grades, which is extremely pocket friendly in nature due to its low maintenance cost.

Comparison with conventional materials

|

Parameters |

Aeron Frp Gratings |

Hot Dip Gi |

Ss |

|

Life Span |

High |

Moderate |

High |

|

Strength To Weight Ratio |

High |

Low |

Low |

|

Life Cycle Cost |

Low |

High |

High |

|

Corrosion Resistivity |

Very High |

Moderate |

High |

|

Chemical Resistivity |

High |

High |

Moderate |

|

Electrical Conductivity |

Low |

High |

High |

|

Emi / Rfi Transparency |

High |

Nil |

Nil |

|

Installation Cost |

Low |

Moderate |

Moderate |

|

Handling |

Very Easy |

Difficult |

Difficult |

|

Anti Skid |

Available |

Na |

Na |

|

Colour Range |

Available |

Na |

Na |

Construction:

FRP grating is developed by wet moulding and hot curing process in a heated mould. For even distribution of loads, the reinforcement is done via continuous fibreglass rovings in alternating layers. The regularly Moulded FRP Gratings have a polyester resin matrix, which contain approximately 35% of glass. The product is available in yellow, grey or green colors, according to RAL.

Accessories:

The product is provided with special support angles, which is concreted into the basement directly.

Fixing Sets:

It is easy to assemble and requires no special tools. Basically, stainless steel fixing sets are utilized for all standard FRP gratings. And, to prevent lifting and sliding, each panel is fixed on at least four points.

Resin Selection:

We meet all the project designs with high proficiency, Aeron FRP Gratings are made available in a variety of color. Some of these include:

- Dark Grey

- Yellow

- Green

|

Resin Type |

Resin Base |

Description |

Flame spread rating ASTM E84 |

|

Type IFR |

Isopthalic Polyester |

Industrial Grade Corrosion resistance & fire retardant |

Class 1, 25 or less |

|

Type I |

Isopthalic Polyester |

Industrial Grade Corrosion resistance in acidic environment |

Non fire retardant |

|

Type V |

Vinyl Ester |

Superior Corrosion resistance & fire retardant |

Class 1, 25 or less |

|

Type P |

Phenolic |

Low smoke and superior fire retardant |

Class 1, 5 or less |

To complement any project design, Aeron FRP Gratings are made available in variety of colors. Standard colors available for FRP Grating: Dark Grey, Yellow and Green. Custom colors are made available upon request.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese